The automatic lathe plant produces various parts used in terminal blocks. The introduction of CNC lathes has contributed to automation of the manufacturing process with multiple machines being controlled by a small number of operators. We have also put into operation numerous other pieces of hardware, including a centrifuge and ultrasonic cleaning machines.

Refer to this section for the list of equipment used in the inspection department.

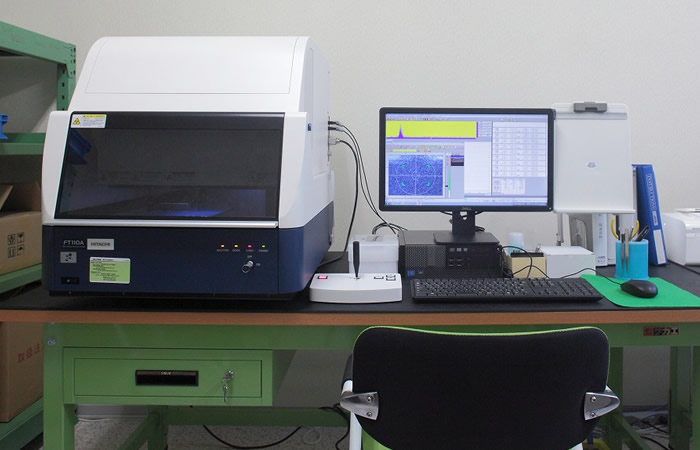

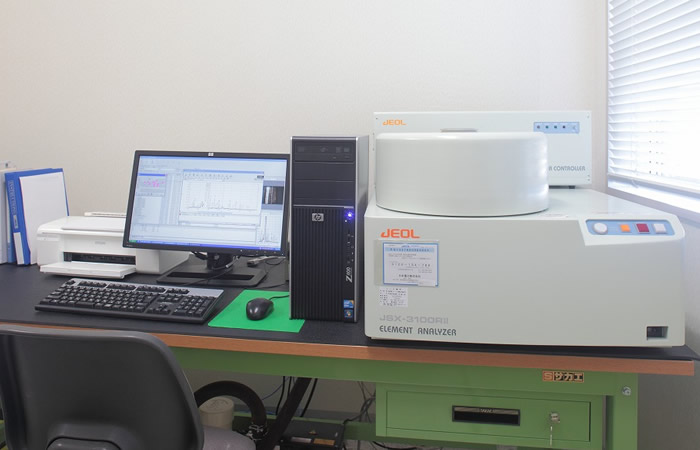

| Equipment | Number |

|---|---|

| X-ray Fluorescence Spectrometer | 2 |

| X-ray Fluorescence Analysis thickness meter | 2 |

| Paperless Recorders | 5 |

| Environmental Test Chamber | 5 |

| Bench-Top Type Temperature(&Humidity) Chamber | 1 |

| Withstand voltage tester | 9 |

| Twisting tester | 2 |

| Load measuring instrument | 4 |

| Impulse Voltage Generators | 1 |

| Thunder surge tester | 1 |

| Electrodynamic Vibration Test Systems | 1 |

| Salt Spray Test Instrument | 1 |

| Industrial Microscopes | 1 |

| Measuring Microscopes | 5 |

| Image Dimention Measuring System | 2 |

| Manual Floating-type Coodinate Measuring Machine | 1 |

| DC stabilized power supply | 7 |

| 3D scanner type coordinate measuring machine | 1 |