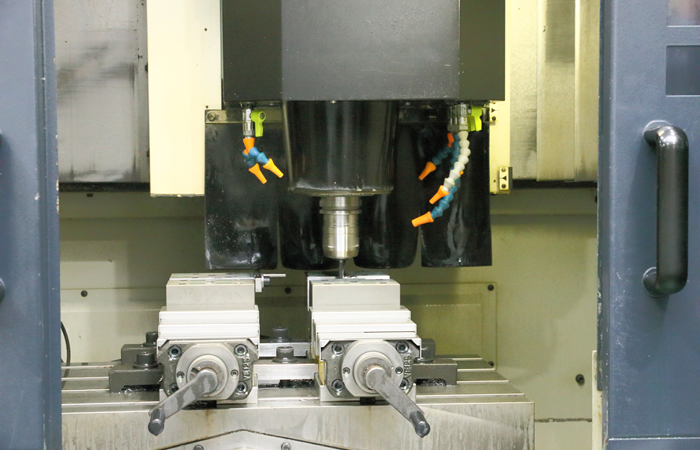

The company’s mold plant produces and maintains die sets used to manufacture molded parts for terminal blocks.

This plant is fitted with advanced equipment including a 5-axis CNC vertical machining center, still rarely seen even in Japan, and we continue to actively introduce latest technology solutions for developing, designing and manufacturing new products.

Refer to this section for the list of equipment used in the mold plant.

| Equipment | Number |

|---|---|

| Five-axis machining center(MAKINO) | 1 |

| NC milling machine(MAKINO) | 1 |

| Milling machine | 1 |

| Wire EDM(Seibu / FANUC) | 7 |

| Surface grinding machines(KURODA) | 4 |

| Vertical machining center(MAKINO) | 2 |

| CNC Jig boring machine(YASDA) | 5 |

| Tapping center(FANUC) | 4 |

| Small Hole EDM(Sodick) | 1 |

| NC Sinker EDM(MITSUBISHI) | 1 |

| Contour machine(LUXO) | 2 |

| Bench lathe(EGURO) | 1 |

| Corner cutter(J.A.M) | 2 |

| Pincut feather | 2 |

| Mold welding machine | 2 |

| Double headed grinder | 2 |

| Surface plate | 1 |

| Precision molds for washing machine | 4 |

| 3D CAD | 9 |

| Microscope measure | 1 |

| CMM(Coordinate Measuring Machine) | 1 |