The molding plant produces molded parts for terminal blocks.

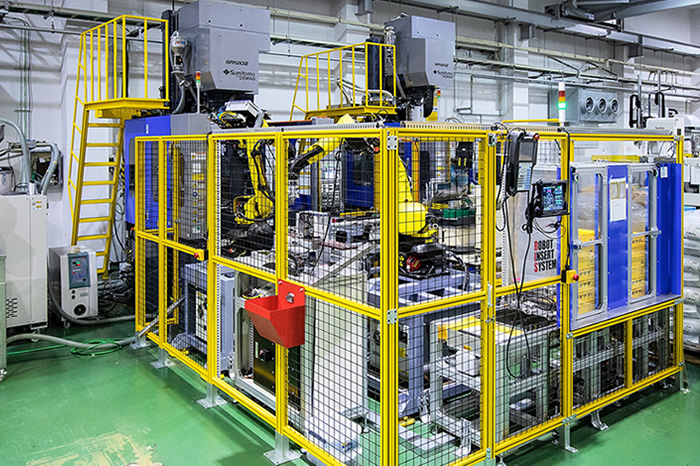

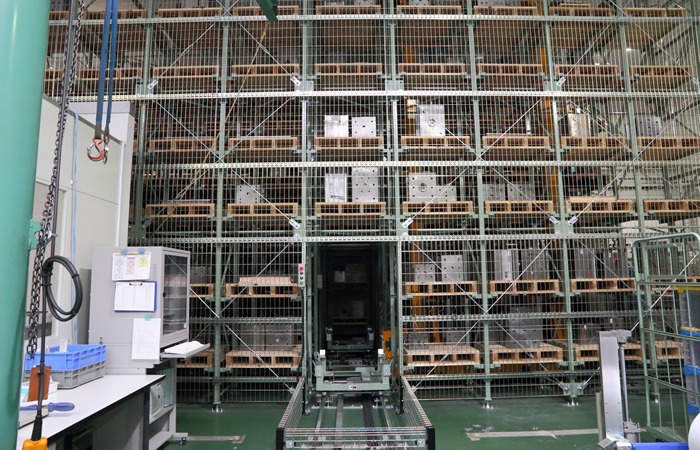

Not only do we use the latest molding machines, but we also take care of the environment through recycling gate runners and other ecological efforts. The molded parts are placed in the trays on the production line with great precision by industrial robots. The molds are placed into an automated storage system after use, which ensures that the limited space of the plant is used most efficiently.

Refer to this section for the list of equipment used in the molding plant.

| Equipment | Number |

|---|---|

| Injection Molding machine(50t) | 1 |

| Injection Molding machine(100t) | 10 |

| Injection Molding machine(150t) | 2 |

| Injection Molding machine(250t) | 1 |

| Injection Molding machine(300t) | 1 |

| Vertical injection molding machine(160t) | 2 |

| Dehumidifying dryer | 16 |

| Tray feeder | 8 |

| Mold temperature controlling machine | 16 |

| Chiller | 16 |

| Crusher | 16 |

| Mold automated warehouse | 1 |

| Take-out robot | 16 |

| Box dryer | 1 |

| Insert molding robot system | 1 |